Brand:

JST SealsItem NO.:

WRPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Turquoise polyester resin wear ring

The function of a hydraulic wear ring is to guide the piston and piston rod of a hydraulic cylinder, absorbing transverse forces. At the same time, it prevents metal-to-metal contact, optimizing the performance of the sealing system.

Standard wear rings for use as rod and piston guides for medium to heavy duty hydraulic cylinders can be manufactured in a variety of fabric reinforced materials including polyester and cotton phenolic composites.

Cotton cloth plays a necessary role in sealing application. A certain amount of cotton thread is required per unit area of 1000 woven fabric, and each fabric layer must be closely bonded together. The content of phenolic resin must be large enough to firmly bond the fabric layers together, so that the fabric or phenolic resin will not loosen during installation and work.

Therefore, the piston seal installed between phenolic sandwich guide rings can have a longer service life.

The phenolic/polyester resin fabric wear ring has a precise guiding effect on the piston and the piston rod moving in the hydraulic cylinder, and can absorb the radial force generated at any time. At the same time, the wear ring prevents metal contact in the sliding portion of the hydraulic cylinder, that is, metal contact between the piston and the cylinder or between the cylinder head of the piston rod. The structure of Phenolic resin fabric and the appropriate oil absorption of cotton fiber can almost make the guide element self-lubricating.

At present, Phenolic resin fabric is the dominant guiding material on the piston and piston rod in heavy-duty walking and industrial hydraulic cylinder.

|

Advantages: 1. It can be fastened simply and quickly without auxiliary tools during installation; 2. Make the sliding surface have no metal contact, thus reducing the damage of metal parts; 3. Has the effect of shock absorption; 4. Increased radial load carrying capacity; 5. Have excellent emergency work in the case of insufficient lubrication; 6. There are precise tolerances and dimensional accuracy. |

|

Color |

Density(g/cm³) |

Compressive Strength(Mpa) |

Friction coefficient(dry) |

Working Temp.℃ |

|

Turquoise |

1.2-1.4 |

320 |

0.14 |

-40~+130 |

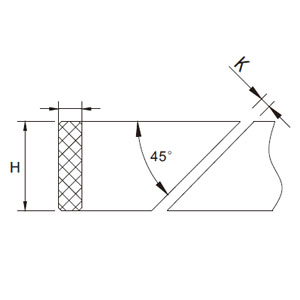

Size:

|

|

|||

|

Dimension

(MM)

|

|||

|

35*30*9.8 |

100*95*15 |

125*118*15 |

160*155*8 |

|

40*35*9.8 |

100*92*15 |

125*119*15 |

160*155*15 |

|

50*45*15 |

100*91*12.5 |

125*120*15 |

160*148*15 |

|

60*55*15 |

100*94*12.5 |

125*120*25 |

160*148*20 |

|

60*54*15 |

100*94*25 |

125*117*15 |

160*153*20 |

|

65*60*15 |

100*94*30 |

130*125*8 |

160*153*35 |

|

70*65*15 |

100*94*22 |

130*125*9.5 |

160*153*40 |

|

70*64*15 |

105*100*6 |

130*124*9.5 |

160*153*45 |

|

70*64*20 |

105*100*9.5 |

130*123*9.5 |

165*157*9.5 |

|

70*65*20 |

105*96*12.5 |

130*125*40 |

165*158*15 |

|

75*69*15 |

105*100*15 |

130*120*10 |

170*165*9.5 |

|

75*69*25 |

110*105*6 |

135*130*8 |

170*164*9.5 |

|

75*70*15 |

110*105*8 |

135*130*9.5 |

170*165*15 |

|

75*70*25 |

110*105*9.5 |

135*128*9.5 |

170*164*15 |

|

80*75*8 |

110*101*12.5 |

135*125*10 |

170*162*15 |

|

80*75*9.5 |

110*101*15 |

135*128*15 |

165*159*30 |

|

80*75*20 |

110*102*15 |

135*128*25 |

165*159*25 |

|

80*74*15 |

110*104*25 |

140*135*8 |

170*162*25 |

|

80*74*20 |

110*104*22 |

140*135*9.5 |

170*162*45 |

|

80*75*15 |

110*104*30 |

140*135*15 |

170*162*50 |

|

85*80*15 |

115*110*6.1 |

140*133*20 |

170*163*9.5 |

|

80*74*30 |

115*110*8 |

140*133*9.8 |

170*158*20 |

|

90*85*6.1 |

115*110*9.5 |

140*128*10 |

180*175*9.5 |

|

90*81*12.5 |

115*105*10 |

140*128*12.8 |

180*175*15 |

|

90*84*12.5 |

115*106*10 |

140*128*17.5 |

180*172*22.5 |

|

90*84*25 |

115*110*15 |

140*128*15 |

185*180*9.5 |

|

90*84*30 |

115*106*15 |

140*135*25 |

185*173*22 |

|

90*85*30 |

115*107*15 |

140*133*35 |

175*167*15 |

|

90*85*15 |

120*115*8 |

140*133*40 |

175*167*25 |

|

90*82*15 |

120*115*9.5 |

145*140*8 |

190*185*15 |

|

85*77*15 |

120*110*10 |

145*140*9.5 |

190*184*15 |

|

95*90*6.1 |

120*111*15 |

145*138*9.5 |

190*182*22.5 |

|

95*90*8 |

120*114*15 |

145*137*15 |

200*188*22.5 |

|

95*90*9.7 |

120*111*10 |

145*138*15 |

190*182*45 |

|

95*86*12.5 |

120*114*30 |

145*138*20 |

190*182*25 |

|

95*87*15 |

120*112*15 |

145*139*25 |

200*192*22.5 |

|

95*90*15 |

105*96*10 |

150*143*40 |

200*192*25 |

|

100*95*6 |

95*86*10 |

150*143*15 |

200*192*28.5 |

|

100*95*8 |

145*133*12 |

150*143*45 |

190*182*28.5 |

|

100*95*9.5 |

150*138*12 |

150*145*15 |

190*184*20 |

|

90*84*20 |

150*143*15 |

150*143*21 |

200*194*30 |

|

100*94*6 |

125*120*8 |

150*143*22 |

200*195*15 |

|

110*104*6 |

125*120*9.5 |

150*145*8 |

200*195*20 |

|

120*114*6 |

125*118*9.7 |

150*145*9.5 |

|

|

160.8*168.8*8.8 |

125*119*9.5 |

160*155*9.7 |

|

Previous:

WR phenolic resin wear ringNext:

Glass filled nylon wear ringIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2024 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat