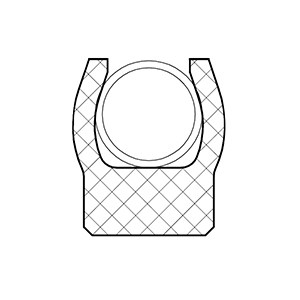

The FHB seal is made of a helical wound spring and a polymer jacket, which is mainly used as a Flange internal face seal.

Brand:

JST SealsItem NO.:

FHBPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50PTFE spring energized seals for cryogenic applications

The FHB seal is made of a helical wound spring and a polymer jacket, which is mainly used as a Flange internal face seal.

In the cryogenic system, due to the serious impact of the relatively severe working environment such as deep low temperature, high vacuum and high pressure, the work difficulty in the design, production, operation and maintenance of the device is greatly increased. Therefore, the sealing effect of the sealing structure is a very important performance index in the cryogenic system. Many cryogenic systems are related to cryogenic liquids. In order to effectively avoid liquid leakage, it is necessary to select a sealing structure suitable for cryogenic environments.

A helical wound spring is most commonly used in static face seal applications and low temperature fields that require high loads. The rotary seal with inclined coil is superior to O-ring in terms of friction, consistency and wear life.

Gaskets are generally used in the form of gaskets for both the flange sealing of valves and the external connection of flange connected valves.

When the gasket seal reaches the designed working low temperature from normal temperature, selecting appropriate gasket materials and increasing the tensile deformation of bolts can ensure that the sealing gasket still has some pre tightening force at the working temperature to maintain the sealing capacity.

|

Advantages: 1. Radial seal for static and dynamic duties; suitable as rod or piston seal. 2. Medium to high spring load for positive sealing, but with some friction. 3. Suitable for service with medium to high system pressure. |

|

Working Conditions |

|||

|

Material |

Temperature range |

Pressure |

Medium |

|

Sealing

ring: Teflon+carbon fiber

Spring: 316SS

|

-50~180℃ |

≤80Mpa |

LNG, Low temperature ethylene |

Previous:

Bidirectional high-pressure ball valve seat sealNext:

Ball valve seat seals for Cryogenic Valve and LNG ApplicationIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2024 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat