JST 1.51” lockdown screw packing seal passed API 6A 21st Edition Annex F PR2 test

JST new design of Lockdown screw packing is made from one PTFE ring and two copper rings. PTFE ring is able to lower the holding force and friction, thus lower the torque. Meanwhile, two copper rings can better protect the LDS body not to be damaged during the twisting and rotating process.

JST has conducted the test to qualify the PR2 performance of 1.51 inch LDS packing seal at L-X -46℃~177℃ ( -50℉~350℉) temperature rating, 15,000psi nitrogen high pressure.

1 Test conditions

1.1 Material: PE001(PTFE)+T1 (Contains over 99% copper)

1.2 Temperature: -46℃~177℃ ( -50℉~350℉)

1.3 Pressure: 15,000psi

1.4 Gas Test Medium: N2

1.5 Sealing Type: Static seal

1.6 Shell test pressure: 22,500psi

1.7 Test Medium for Shell test: Water

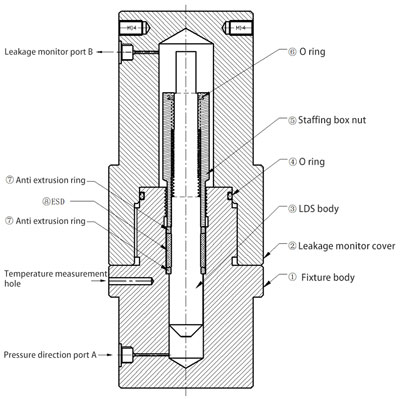

2 Product

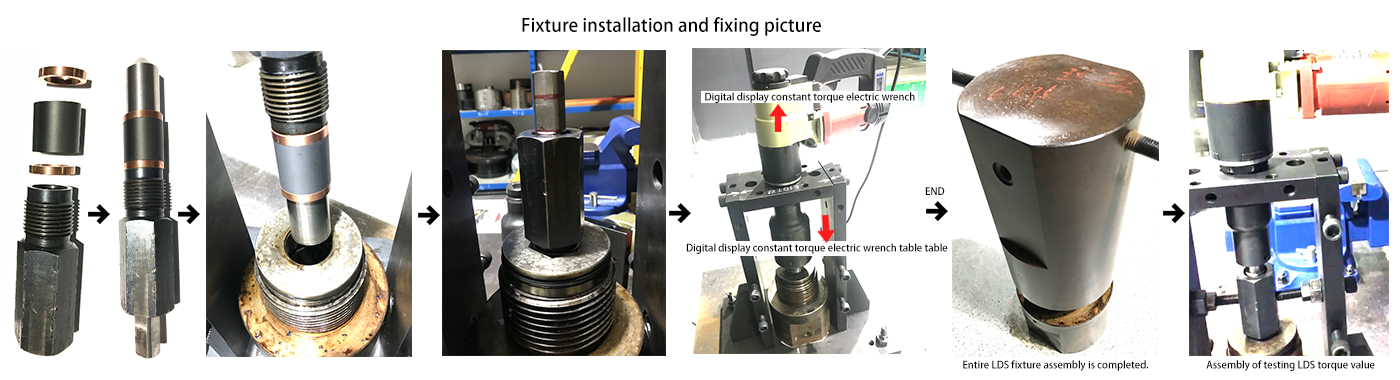

3 Fixture and Assembly

4 Test data

1.51 Inch LDS Seal (ESD) PR2 Test Data

|

No. |

Test Name |

Port |

Temp(℃) |

Pressure (Psi) |

Medium |

Pressure Holding Time(S) |

Pressure drops(Psi) |

Conclusion |

|

1 |

Monitor O-ring sealing performance of Port C |

A |

Ambient Temp |

100 |

N2 |

900 |

6 |

Passed |

|

2 |

Shell test |

A |

Ambient Temp |

22500 |

N2 |

900 |

38 |

Passed |

|

3 |

Pressure test at maximum rated temp |

A |

177 |

15000 |

N2 |

3600 |

92 |

Passed |

|

4 |

Pressure test at minimum rated temp |

A |

-60 |

15000 |

N2 |

3600 |

92 |

Passed |

|

5 |

Temp and pressure cycle test Port A |

A |

Ambient Temp |

7500-15000 |

N2 |

/ |

/ |

Passed |

|

177 |

15000 |

N2 |

3600 |

9 |

Passed |

|||

|

-60 |

15000 |

N2 |

3600 |

27 |

Passed |

|||

|

Ambient Temp |

7500-15000 |

N2 |

3600 |

/ |

Passed |

|||

|

6 |

Pressure test at maximum rated temp |

A |

177 |

15000 |

N2 |

3600 |

66 |

Passed |

|

7 |

Pressure test at minimum rated temp |

A |

-60 |

15000 |

N2 |

3600 |

151 |

Passed |

|

8 |

Maximum rated pressure test |

A |

Ambient Temp |

15000 |

N2 |

3600 |

100 |

Passed |

|

9 |

Minimum rated pressure test |

A |

Ambient Temp |

750-1000 |

N2 |

3600 |

8 |

Passed |

5 Conclusion:

1.51" LDS (Lockdown Screw Seal) packing passed the Pre-qualification testing per API 6A PSL 3G. (PSL 3G will include a shell test pressure of 22.5Ksi for 15K working pressure rated products.), Pressure temperature cycle test as per API 6A 21st Edition Annex F PR2F table F.18 and Torque test as per customer’s requirement; (Torque value test is required before PR2F and after PR2F) at temperature L-X(-46℃~177℃ ( -50℉~350℉)) and working pressure of 15,000 psi with gas as test medium.

New Blog

© Copyright: 2025 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Scan to wechat