Application of JST Lockdown Screw Seals?

Lockdown Screw Seals, also called lockdown screw packing is made from elastomer and two SS metal end caps. It provides a dependable seal in multiple pressure ranges and service environments.

JST has conducted the PR2 test to qualify the existing elastomer/metal lockdown screw packing to 20,000 psi at a temperature range of -50 to 350ºF. This test consisted of a 20,000 psi nitrogen gas proof test along with an API PR2 cycle test at 20,000 psi.

1 Test conditions

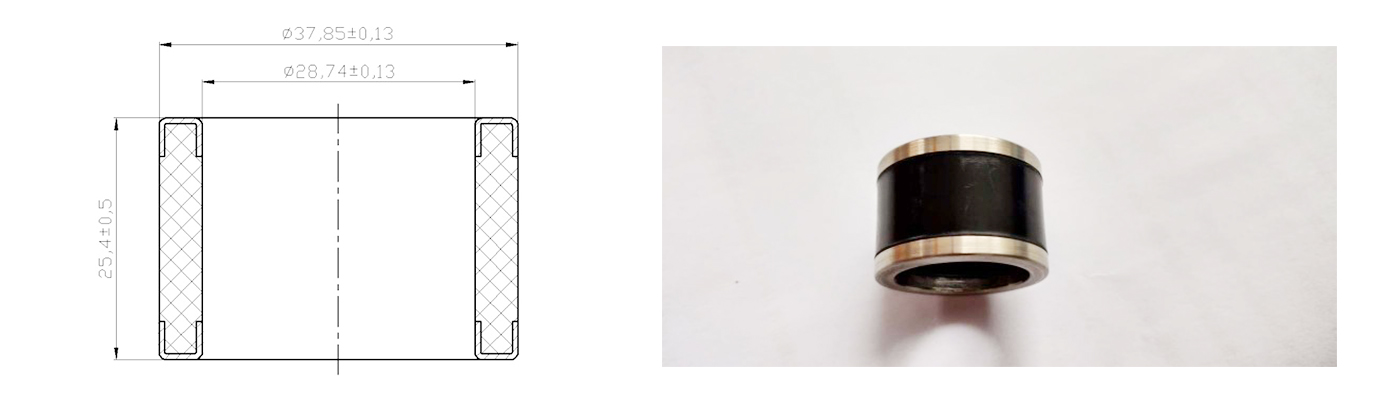

1) Product : Lockdown Screw Seals 1.132X1.495X1”

2) Material: Glass fibre filled HNBR + 316 SS end cap

3) Temperature: -46℃~177℃( -50 TO 350℉)

4) Pressure: 20000 Psi

5) Gas Test Medium: N2

6) Hydrostatic Test Medium: N2

7) Sealing Type: Static seal

2 Product

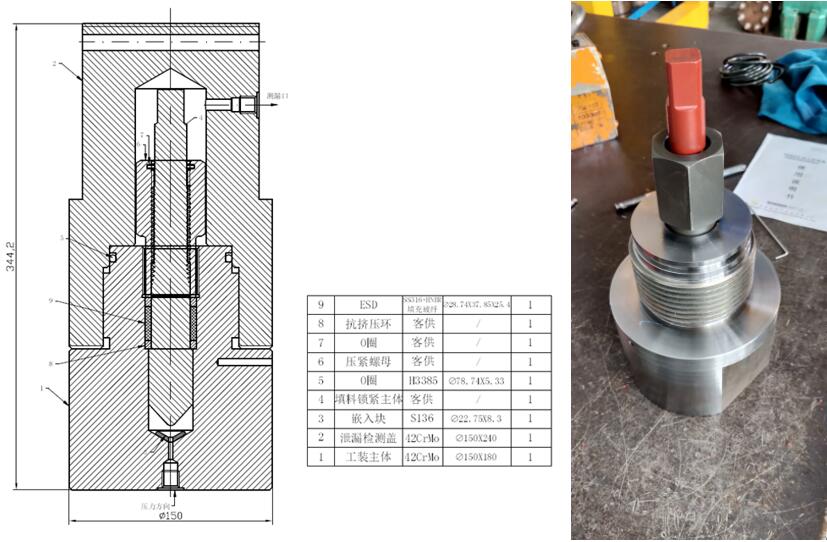

3 Fixture and Assembly

4 Test procedure

4.1 Ambient Proof Test(Min torque 677.5 N.M, Max torque 1084N.M)

4.1.1 Insert the LDS packing assembly into the fixture, fix the fixture, use a torque wrench to tighten the LDS packing compression nut in a clockwise direction with a torque of 800N.M.

4.1.2 Record the operating torque of LDS body.

4.1.3 Connect the N2 line to the fixture, Place fixture in the oven.

4.1.4 Apply 20000 psi with 5000 psi increments to the fixture. Hold the 20000 psi pressure for 15 minutes and monitor the bubble line for leakage. If test is successful, proceed to PR2 test.

4.1.5 If leakage occurs, tighten the LSD packing torque stuffing box nut to 813N.M. Repeat steps 1.2 to1.4.

4.1.6 If necessary, repeat steps 1.2 to 1.4, increase the torques on the stuffing box nut in 67.75N.M increments until the packing seals or the stuffing box nut torque reaches 1084N.M.

4.2 API PR2 test preparation:

4.2.1 Install o-ring and back-up ring into groove on body, Thread the Leak Detection Cap on to the fixture and set-up the N2 gas pressure and leak detection lines. Connect thermocouples to the two locations on the fixture body.

5 Procedure (per API 6A Appendix F PR2)

5.1 Room temperature pressure holding test (room temperature, 20000 psi)

5.1.1 Apply 20000 psi to the fixture and hold for 15mins.

5.2 Pressure test at maximum rated temp(177℃/350℉, 20000 psi)

5.2.1 Release pressure and heat the fixture to 177℃/350℉.

5.2.2 Apply 20000 psi to the packing and hold the pressure for one hour.

5.3 Pressure test at minimum rated temp(-46℃/-50℉, 20000 psi)

5.3.1 Release pressure and cool the fixture to -46℃/-50℉.

5.3.2 Apply 20000 psi to the LDS packing and hold the pressure for one hour.

5.3.3 Release pressure and warm the fixture to 27℃/80℉.

5.4 Temp and pressure cycle test (-46℃/-50℉, 20000 psi)

5.4.1 Apply 12000 psi at 27℃/80℉, raise the temperature to 177℃/350℉, hold the pressure at 10000-20000 psi during the heating process, and apply 20000 psi when the temperature is stable at 177℃/350℉;

5.4.2 With pressure on the fixture, hold the temperature at 177℃/350℉ for one hour;

5.4.3 Lower the temperature to -46℃/-50℉, hold the pressure at 10000-20000 psi during the cooling process, and apply 20000 psi when the temperature is stable at -46℃/-50℉;

5.4.4 With pressure on the fixture, hold the temperature at -46℃/-50℉ for one hour;

5.4.5 Holding 20000 psi on the packing, raise the temperature to 27℃/80℉, holding pressure at 10000-20000 psi during the heating process;

5.4.6 When temperature stabilizes at 27℃/80℉, release the pressure. Heat the fixture to 177℃/350℉;

5.4.7 Apply 20000 psi to the packing and hold for one hour, then release pressure;

5.4.8 Cool the fixture to - -46℃/-50℉;

5.4.9 Apply 20000 psi to the packing and hold the pressure for one hour, then release pressure;

5.4.10 Heat the fixture to ambient temperature;

5.5 Ambient temperature and high pressure holding test (Ambient temperature, 20000 psi)

5.5.1 Apply 20000 psi to the packing and hold the pressure for one hour.

5.6 Ambient temperature and low pressure holding test (Ambient temperature, 2000 psi)

5.6.1 Release pressure and reapply 2,000 psi to the packing and hold for one hour.

5.7 Release pressure and disassemble the test fixture.

6 Acceptance standards

During each pressure maintaining period, no visible leakage or pressure drop shall be less than 5% or 3.45 MPa (500 psi) of test pressure, whichever is the lesser of the two as acceptance.

7 Test conclusion

PR2 performance of Lockdown Screw Seals pass API 6A 21st Edition Annex F PR2 at temperature L-X (-46℃~177℃( -50 TO 350℉)) and working pressure of 20000 psi with gas as test medium.

Previous :

5” Packer Element Test ReportNext :

Applications of large size FS Seal and P sealNew Blog

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat