Why Do Engineers Prefer JST BVR series for Ball Valve Seats?

When it comes to unidirection Radial seal for the Ball valve seat, our customer would always prefer to choose JST style “BVR”, but why is that?

The answer lies in its optimized sealing geometry and pressure-activated design. The BVR series is made of a canted level spring and a polymer jacket, which is mainly used as a stem seal. Under pressure, the seal lip is energized and tightly pressed against the valve seat, ensuring excellent tightness even at high pressure levels.

With proper material selection—such as PTFE compounds or filled polymers—the seal performs reliably under high pressure, temperature fluctuations, and aggressive media commonly found in oil & gas, chemical, and industrial applications.

Finally, customers value the ease of installation and consistency in performance. The JST style “BVR” is designed for precise fitment, minimizing installation errors and ensuring repeatable sealing results across different valve sizes and operating conditions.

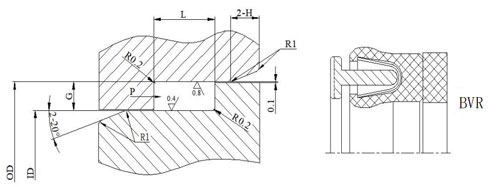

Hereunder is technical recommendations for groove dimensions.

|

Working conditions |

ID(mm) |

G(mm) |

OD (mm) |

L +0.2 /(mm) |

Minimum sizeH(mm) |

|

10000psi -60~180℃ |

7~15 |

2.4 |

9.5 |

9.5 |

3.4 |

|

15~30 |

3.1 |

10 |

10 |

5.0 |

|

|

30~90 |

4.7 |

12.5 |

12.5 |

6 |

|

|

90~600 |

6.1 |

16 |

16 |

7 |

|

|

600~1200 |

9.5 |

28 |

28 |

9.5 |

New Blog

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat