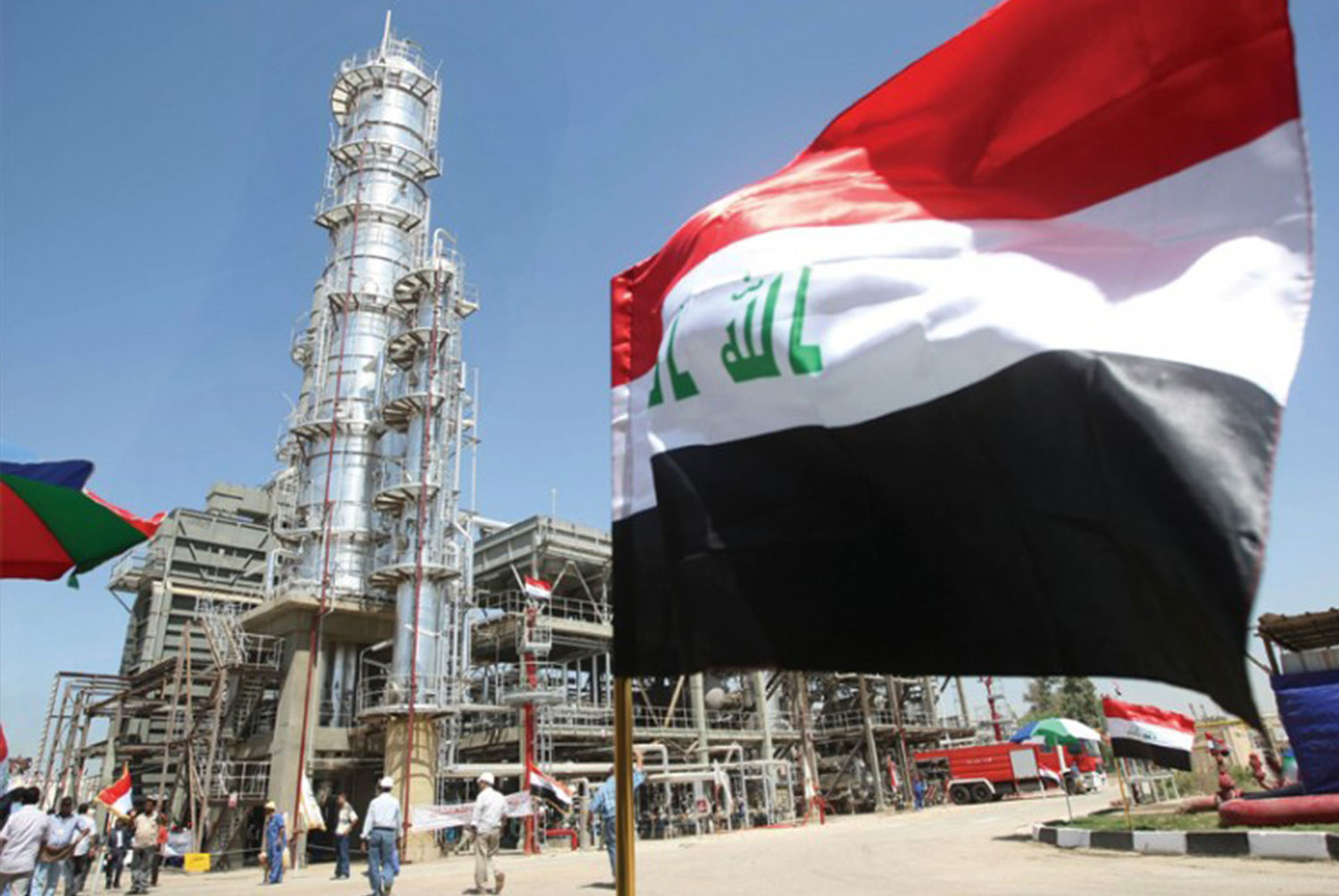

Iraq has announced that the re-operation of Karbala and Beiji oil refineries would meet 100% of its local demand for petroleum products. The Karbala refinery will fill 80% of the current import need after operating at full capacity while indicating that the production capacity of the Baiji refinery will reach 300 thousand barrels after the completion of its reconstruction and rehabilitation. Thus, it can, with Karbala refinery, fill the local need by 100%. “The Karbala refinery is currently operating under trial operation, but if it is completed and operating at full capacity, it will compensate and cover 80% of the import,” said MP Kazen Al- Touki, noting that the Baiji refinery will complete the remaining 20 %. Karbala oil refinery, located near Karbala province in Southern Iraq, was inaugurated in April 2023 with a production capacity of 140,000 barrels per day (bpd). The US$6bn refinery, which was developed by ATCONZ and Invest International (Italy), is supplied with crude oil via a pipeline from the southern oil fields in Basra. Construction started in 2014. Iraq has 16 refineries, for a total nominal capacity of 1 mbpd. The main refineries are Baiji, Basra, Daura, and Kalak. Source: EGYPT OIL & GAS

ADIPEC, taking place on 2-5 October 2023 in Abu Dhabi, is the world’s largest and most inclusive gathering for the energy industry. Over 2,200 companies from across the world, representing the entire energy ecosystem and beyond, will come together at the ADIPEC Exhibition to showcase the latest strategies and innovations that are defining the future of energy. The exhibition will feature 54 NOCs, IOCs, NECs and IECs and 30 international exhibiting country pavilions, uniting under a common goal while presenting diverse perspectives and ideas, and forging the game-changing partnerships that will enable the world to decarbonise faster, together. Alongside ADIPEC’s 16 exhibition halls, it will host four specialised industry areas – the Decarbonisation Zone, Maritime & Logistics Zone, Digitalisation in Energy Zone, and Manufacturing & Industrialisation Exhibition & Conference. These dedicated zones will enable the industry to strengthen existing business partnerships and form new models of cross-sector collaboration to unlock and maximise value across businesses and drive future growth. Visit JST at the ADIPEC Exhibition, Abu Dhabi National Exhibition Centre, Abu Dhabi, UAE. Hall 13, Booth 13530. JST's products and services cover oil & gas drilling, semiconductor, new energy, construction machinery, aerospace, nuclear & wind power, medical equipment and other industries, meet the complex and harsh working conditions and technical requirements of various industries with its strength. JST has businesses in more than 50 countries and regions, and established partnerships with top industrial companies worldwide. JST is winning global recognition and attention.

Italy’s engineering, drilling, and construction services giant Saipem is on a roll, as it lined up its second batch of contracts in two days and its third one since the start of this month. The latest set of deals was secured with two oil majors. These assignments, awarded by Eni and BP, come with a total value of around $700 million. Scarabeo 5 semi-submersible drilling rig; Source: Saipem The Italian giant won the first contract with Eni Congo for the conversion of the Scarabeo 5 semi-submersible drilling rig into a separation and boosting plant – a floating production unit (FPU), which is a semi-submersible production platform that receives the production fluids from wellheads riser platforms, separates the gas from liquids and boosts the gas to feed the nearby floating LNG (FLNG) unit. After an agreement signed early this year for the execution of preliminary engineering and procurement activities, the new contract entails the engineering, procurement, construction, transportation and commissioning of the FPU to be installed offshore the coast of the Republic of Congo, located northwest of the Djeno Terminal, in a depth of about 35 metres. The commissioning of offshore works and the start-up of the FPU are slated for 4Q 2025. According to Saipem, this deal is part of Eni’s Congo LNG project, the country’s first natural gas liquefaction project that is expected to reach an overall LNG production capacity of 3 million tons per year – approximately 4.5 billion cubic meters per year – from 2025. The Congo LNG project is expected to exploit the gas resources of the Marine XII project, fulfilling power generation needs while fuelling LNG exports and supplying new volumes of gas to international markets focusing on Europe. The project entails the installation of two floating natural gas liquefaction plants at the Nenè and Litchendjili fields. The first FLNG plant, currently under conversion and with a capacity of 0.6 million tonnes per year, is expected to begin production in 2023, while the second FLNG plant, already under construction, is expected to become operative in 2025, with a capacity of 2.4 MTPA. Source: offshore-energy

With the development of technology and social progress, humans are gradually influencing and changing the ecological environment on Earth, and many organisms have been in deep water due to human relations. According to reports, after 11 years, organisms living in the Gulf of Mexico are still suffering from the 2010 oil spill. The Gulf of Mexico oil spill, also known as the BP oil spill or the Deepwater Horizon oil spill, was an oil spill incident that occurred on April 20, 2010 outside the Gulf of Mexico. The cause was a blowout and explosion on a deep-sea drilling platform called Deepwater Horizon rented by BP, resulting in an oil spill accident. After the Gulf of Mexico oil spill, a large area of water near the spill was contaminated, and many fish, birds, marine organisms, and plants were severely affected, such as illness and death. The US government's investigation report in November pointed out that 6104 birds, 609 sea turtles, and 100 dolphins, including mammals, have died. This number may include animals that died from natural causes, and all data on deaths caused by deep-sea oil spills is still uncertain. At present, it is unclear when the oil concentration in seawater can return to the normal level before the incident. So why the human being build oil wells offshore? Because there are very rich oil resources in the ocean. According to statistics, the world's proven offshore oil reserves now account for more than 25% of the world's known oil reserves, and offshore oil wells are becoming more and more common. Exploitation and use of these offshore oil resources will contribute to the development and progress of mankind. However, every coin has two sides. When human beings enjoy the convenient life that resources bring to us, we are also destroying the ecological environment of the earth due to our demands for natural resources. The U.S. Gulf of Mexico crude oil spill is not the only marine oil spill in the world, and it is still possible to happen in the future. What humans have to do is to avoid oil spills as much as possible and to avoid pollution to the natural environment. Seals are key components of petroleum drilling control equipment, mainly used to control wellhead pressure during drilling, workover, oil testing, and other processes, effectively preventing blowout accidents and achieving safe construction. By using high-quality Oil and gas seals, we can effectively prevent oil leakage from the equipment. From this, it can be seen that sealing is not a trivial matter. Whether in oil or gas transmission equipment, we must fully test the performance of the seals to prevent leakage. JST Seals are committed to our mission of "Fuel social development of mankind via sealing technology". We can help you develop, design, produce, and test seals.

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat