Bidirectional high-pressure ball valve seat seal is a type of seat sealing that can withstand bidirectional pressure, with good low-temperature performance and airtightness, and is widely used in 6D ball valves.

Brand:

JST SealsItem NO.:

BVRPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50

Bidirectional high-pressure ball valve seat seal

In recent years, with the continuous development of petrochemicals and shale gas, and the widespread application in the air separation industry, liquefied petroleum gas, low-temperature ethylene industry, especially natural gas projects, the demand for ball valves in engineering projects has been increasing, which has also led to an increasing demand for ball valve seals. At present, ball valve sealing with unidirectional sealing is the majority used in the market. JST has developed a high-pressure bidirectional sealing component, which can provide you with feasible bidirectional sealing solutions for ball valve high-pressure equipment.

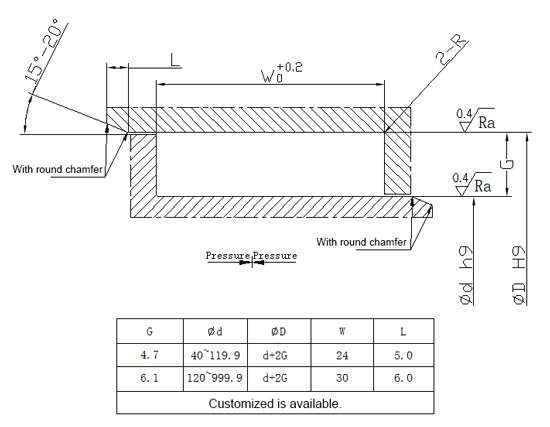

Bidirectional high-pressure ball valve seat seal is a type of seat sealing that can withstand bidirectional pressure, with good low-temperature performance and airtightness, and is widely used in 6D ball valves.

The product fully meets the pressure working conditions requirements of the current 6D ball valve, ranging from 0 to 47MPa, with good sealing performance, and the sealing element will not extrude and deform. After use, the product maintains a good structure. Under bidirectional pressure (high pressure) ambient temperature, there is no leakage at each stage, and the product has a service life of over 1 year.

Application:

1. 6D ball valve bi-directional seat and extension can be used for other bi-directional pressure sealing

2. Bi-directional pressure bearing piston or rod sealing to reduce product deformation and ensure sealing effect

|

Features: 1. High pressure resistance 2. Bidirectional alternating pressure bearing 3. The overall force of the structure is uniform 4. High reliability ambient temperature 2500LB (47MPa) bubble free test verification |

| Working Conditions | |||

| Temperature range |

Pressure |

Medium |

Material |

|

-46 ℃~150 ℃ |

2500LB (47MPa) |

Natural gas, H2S, oil, gas, water |

P1031/PEEK/316 stainless steel |

Size:

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat