How to Choose the Right Size O-Ring for a Hydraulic System?

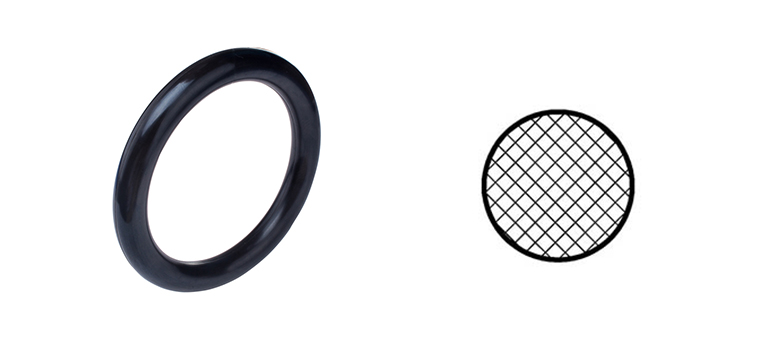

O-ring, also called O-shaped rubber ring, are used to prevent leakage and prevent external contaminants from penetrating the hydraulic system. It can be sealed within various pressure, temperature and tolerance ranges. It has small volume, light weight and can be reused. It has various sizes and materials to choose from.

Product specification

The size of the O-ring is determined by the inner diameter, outer diameter and cross section. When selecting the inner diameter of O-ring, some space needs to be reserved to solve the problem of thermal expansion.

Do not stretch the O-ring more than 5%, because excessive stretching will flatten the cross section of the O-ring. The cross section of O-ring varies from a few millimeters to tens of millimeters. When selecting O-rings for hydraulic applications, it is very important to understand the depth of the groove. Only when the cross-section of the selected O-ring is correct, can extrusion and tearing problems be avoided and the sealing effect be ensured.

Material Science

O-rings are available in a variety of materials, including NBR, EPDM, FKM, etc.

NBR has excellent hydraulic oil resistance and can be used in the temperature range of - 35 ° C to + 120 ° C. It is a copolymer of butadiene and acrylonitrile. With the increase of nitrile content, it has stronger tolerance to hydraulic oil, but its elasticity becomes worse. Although NBR has poor ozone resistance, UV resistance or weather resistance, it has excellent compression set resistance, tear resistance and wear resistance. O-rings made of nitrile rubber are usually the best choice for hydraulic applications.

The O-ring processed by EPDM has excellent heat resistance, water resistance, steam resistance, ozone resistance and ultraviolet resistance. It is very effective in sealing phosphate hydraulic oil and can replace nitrile rubber under some application conditions.

FKM O-ring has high temperature resistance, grease resistance, fuel resistance, silicone oil resistance and many other media. It is very suitable for aviation applications. Increasing the fluorine content in FKM will increase the chemical resistance, but the low temperature resistance will be weakened. Viton can be used with non flammable hydraulic oils and is a suitable choice for hydraulic applications in some cases.

Maximum pressure and operating temperature range

Another important factor to consider in selecting the correct O-ring size is the maximum pressure and operating temperature range.

The maximum pressure of O-ring material can be as high as 25 MPa, and the operating temperature range can vary from - 40 ° C to + 200 ° C. When selecting O-ring, its maximum pressure and working temperature shall not exceed its own limit. When the working condition exceeds its maximum pressure or working temperature range, the chemical resistance, flexibility, tear resistance, wear resistance, weather resistance and other properties of the O-ring may be damaged.

When you choose a suitable O-ring for hydraulic applications, the inner diameter, outer diameter, cross section, material, maximum pressure and operating temperature range are important parameters to be considered. Although O-rings are very small and cheap components in the hydraulic system, they are very important to hydraulic performance and need to be carefully selected.

Previous :

What is SPGO seal?Next :

CASE STUDY---S Seal REDESIGNNew Blog

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat