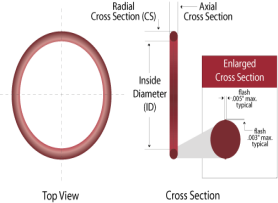

O ring is a type of seals with solid rubber material or PTFE and an O-shaped cross section.

Brand:

JST SealsItem NO.:

ORPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50NBR HNBR FKM PTFE O ring

O ring is a type of seals with solid rubber material or PTFE and an O-shaped cross section. Because its cross section is O-shaped, it is called O-shaped rubber ring. It is one of the most widely used hydraulic and pneumatic transmission systems.

O-ring is a circular rubber ring with circular section. It is mainly used for mechanical parts to prevent the leakage of liquid and gas media under static conditions. In some cases, it can also be used as a dynamic sealing element for axial reciprocating motion and low-speed rotating motion. Different materials can be selected according to different conditions.

For different kinds of fixed seal or dynamic seal applications, O-ring is both effective and economical.

O-ring is a two-way sealing element. The initial compression in radial or axial direction during installation endows the O-ring with its own initial sealing ability. The total sealing force is composed of the sealing force generated by the system pressure and the initial sealing force, which increases with the increase of the system pressure. O-rings play an outstanding role in static sealing occasions. However, O-rings are often used in appropriate dynamic situations, but they are limited by the speed and pressure at the seal.

Material: NBR/ HNBR/ VITON/ AFLS/ EPDM/PU/FFKM/PTFE

|

Advantages: 1. Preventing leakage of fluids. |

| Working Conditions | |

| Temperature | Medium |

| -32 to +204℃ (depends on different material) | oil, water, air and gas etc |

|

Size: ID: 0.74-399.mm |

|

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat