Why FEA is important for valve stem packing seal?

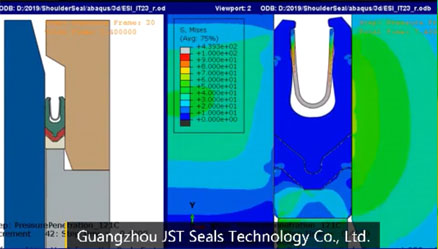

Finite Element Analysis (FEA) is extremely important in critical seal design. JST conducted PR2 tests as per API6A, as well as FEA to its FS seal, S seal, valve stem packing seal, valve face seal. So why FEA is important and necessary?

1. Seal failure prediction from cracks, leaks, or deformation, allowing a better-designed product or reverse-engineering of existing problems to discover root causes.

2. Assembly force requirements to install the seal, allowing end-users to determine whether specific tooling is needed.

The gate valve stem packing seal assembly and valve seat seal contribute to the overall performance of industrial operations. They serve the vital task of keeping oil and liquids in while keeping contaminants out, giving a reliable seal for superior performance.

The FEA helps JST to choose the best materials, and optimize spring energized seal design details.

Previous :

Why Are Hydraulic Seals Important?New Blog

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat