JST HNBR Seals (Material H3385): Engineered for Extreme Performance

JST’s advanced HNBR compound, designated by material code H3385 (HNBR85), is a premium elastomer specifically formulated for demanding rubber sealing applications. Renowned for its exceptional durability and chemical resistance, this material sets a high standard for reliability in critical environments.

Key Properties & Certifications:

NORSOK M-710 Compliance: Successfully passes the stringent requirements of NORSOK M-710 Edition 3 RGD Test, confirming its suitability for the harsh conditions of the oil and gas industry.

API 6A & Sour Service Validation: Qualified under API 6A, 21st Edition, Annex F.1.13.5.2 immersion testing for Material Class FF/HH. It meets the 10% H2S design validation procedures and complies with the sour aging acceptance criteria outlined in ISO 23936-2:2011, ensuring outstanding performance in sour (H2S-containing) environments.

Wide Operational Temperature Range: Features a low-temperature retraction (TR10) value of -31.5°C, enabling reliable operation in extreme cold. The effective service temperature range spans from -31.5°C to 150°C, providing exceptional flexibility and thermal stability.

Common Applications:

Thanks to this robust combination of properties, JST HNBR (H3385) is the material of choice for various critical secondary seals, including but not limited to:

P-Seals

Proven Performance: Demonstrating real-world reliability, we have successfully tested two of our S-Seal designs using this material, both of which passed the rigorous PR2 test.

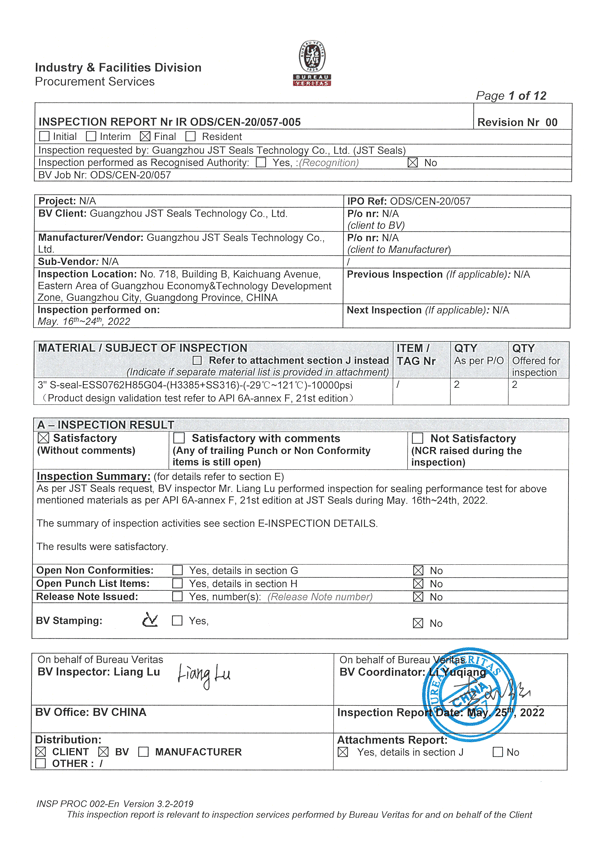

H3385 3''S-seal PR2 test report

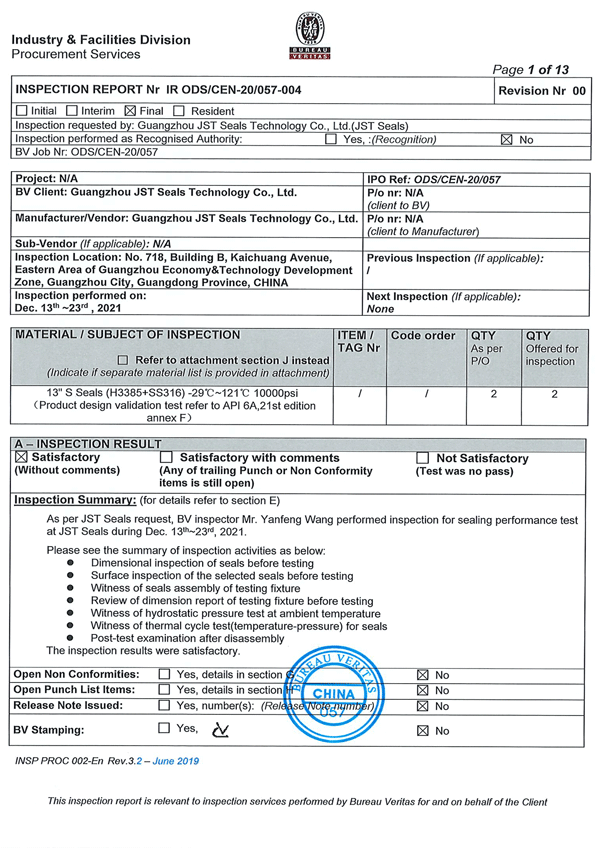

H3385 13''S Seal PR2 test report

New Blog

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat