S Seals are well suited for sealing wellheads, connectors, downhole tools, high pressure valves and other demanding oil and gas applications. The non-extrusion springs can be fabricated from different metals.

The S seal is made of spring and rubber material could be NBR, HNBR, FKM ect.

Brand:

JST SealsItem NO.:

ESSPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50HNBR S seal for downhole application

Wellhead is a key component of oil and gas infrastructure. Wellhead sealing materials need to withstand high pressure and high temperature.

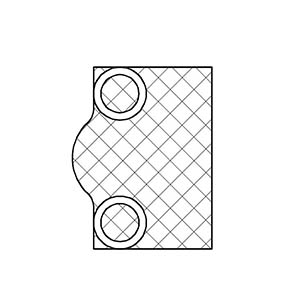

S-seal is a compact one-piece seal design with anti extrusion elastomer with two molded anti extrusion springs at the outer edge. Its unique design integrates two non extrusion devices and a sealing element into an overall structure to provide two-way sealing. At the same time, combined with a simple symmetrical contour non extrusion device, headless coil springs are used on both sides of the seal, allowing a large extrusion gap to be bridged under high pressure. Non extruded equipment (when made of the following materials) limits metal seals to static applications. S seal is a preferred design which attack by oilfield media where an O ring cannot survive the maintenance-free life cycle of the equipment.

|

Product Highlights: 1. Alternative engineered seal design to using T Seals or O-Rings, traditional S Seals utilize metal spring for supporting sealing of various extrusion gaps. |

| Working Conditions | |||

| Temperature range | Pressure | Medium | |

| 40~350F | ≤12.5kPsi | gas and water | |

Size:

3.5", 4.5", 5", 7"

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat