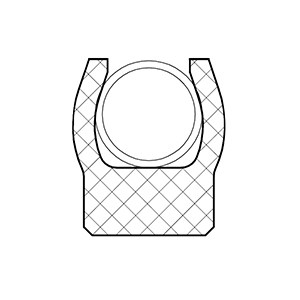

The FDB seal is made of a helical wound spring and a polymer jacket, It is the best choice for vacuum, gas and low-temperature flange sealing applications.

Brand:

JST SealsItem NO.:

FDBPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Helical spring energized seals for oil and gas application

The low temperature PTFE spring energized seal for the valve is a single piston seal. When the working pressure is greater than or equal to 1500LB, a high-strength backup ring can be added to protect the sealing lip from damage. PTFE elgiloy lip seal is composed of PTFE+ Helical spring, and different materials can be used for different temperatures and pressures. Usually used for 6D ultra-low temperature (- 196 °) and normal temperature.

It has high spring load, good sealing integrity under low pressure, and can be used for internal and external pressure. It is the best choice for vacuum, gas and low-temperature flange sealing applications.

|

Advantages: 1. Material compound passed API 6A FF/HH Immersion Testing; 2. Passed BS6364 test(-196℃); 3. High load helical wound spring with small deflection range; 4. Rigid spring acts as a energizer to resist low-temperature shrinkage; 5. NACE-approved energizers available for oil and gas use; 6. One-way or two-way design is available; 7. With single spring or double spring design; |

| Working Conditions | |||

| Material | Temperature range | Pressure | Medium |

|

Sealing ring: Teflon+carbon fiber

Spring: 316SS

|

-196~100℃ | 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB | LNG, Low temperature ethylene |

|

FDB For valve end face |

||||||

|

Groove DWG:

|

||||||

|

Temperature Rating |

JST Series |

Spring |

0~900(LBS) |

900~2500(LBS) |

G=(OD-ID)/2 Standard CS:G=(OD-ID)/2 |

L Value |

|

(-196℃~100℃) |

FDB |

Golden Elgiloy |

|

|

3.1 |

4.8 |

|

4.7 |

7.1 |

|||||

|

6.1 |

9.5 |

|||||

|

6.9 |

10 |

|||||

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat