Brand:

JST SealsItem NO.:

FDRPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Elgiloy spring ball valve seals for cryogenic applications

In LNG operations, valves can regularly encounter temperatures below -320° F (-196° C) and pressures above 750 pounds per square inch (psi). They are also subjected to periodic variations in temperatures known as “thermal cycling,” which can result in hardware expansion as well as shrinkage and material stresses. These factors make reliable, long-term valve operation an engineering challenge.

LNG is flammable, explosive and easy to expand. In order to reduce LNG accidents and improve the safety of LNG ball valve, it is necessary to put forward strict sealing performance requirements. The current situation and shortages of the traditional sealing forms commonly used in LNG ball valves. After research, the basic structure and sealing principle of lip seal make it very suitable for the valve stem, valve seat, body cover and other parts of LNG ball valves. The method of using lip seal can realize the piston effect valve seat of ball valves. The use of lip seal not only enhances the sealing effect of valve stem, valve seat, body cover and other parts of the ball valve, but also realizes the function of overpressure relief after LNG gasification to ensure the safe operation of the system.

Sealing success factors:

To provide superior protection against leakage in cryogenic valves for LNG, seals should have:

1. Jacket material that tolerates thermal cycling

2. An energizer to compensate for shrinkage

3. Anti-extrusion lip geometry

Sealing cryogenics is a balancing act of many factors such as spring force, surface finish, friction and allowable leakage. In JST, we would recommend TMF as jacket material, and Golden Elgiloy Helical Spring as energizer. When the pressure is more than 900LBS, an anti-extrusion ring is required; With the right material formulation and design, they can actually provide much better sealing service than alternative technologies.

Low temperature cryogenic seals application:

Rocket propulsion Filling Systems

LNG Compressors

Cryogenic Valves Stem Seals

Cryogenic Butterfly Seat Seals

Cryogenic Transfer Pumps

LNG Fueling Systems

Petroleum

Scientific Instrumentation

Specialty Gas Manufacturing

|

Advantages: 1. Material compound passed API 6A FF/HH Immersion Testing; 2. Passed BS6364 test(-196℃); 3. High load helical wound spring with small deflection range; 4. Rigid spring acts as a energizer to resist low-temperature shrinkage; 5. NACE-approved energizers available for oil and gas use; 6. One-way or two-way design is available; 7. With single spring or double spring design. |

|

Working Conditions |

||

|

Temperature range |

Pressure |

Medium |

|

-196~100℃ |

150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB |

LNG, Low temperature ethylene |

|

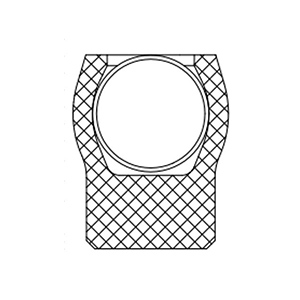

FDR two-way valve seat seal |

||||||

|

|

||||||

|

Cross Section Code |

P |

Recommended ID(mm) |

Back pressure |

Groove Width-G |

Groove Length-L |

Maximum fillet radius-R |

|

D |

≤600LB |

120>d≥40 |

Y |

4.7 |

20 |

0.8 |

|

E |

≤600LB |

700>d≥120 |

Y |

6.1 |

26 |

0.8 |

|

I |

Non-standard specification code (please specify the groove size when ordering), when the pressure P>900LB, an anti-extrusion ring needs to be added, and L is the minimum installation size. |

|||||

Previous:

Helical spring energized seals for oil and gas applicationNext:

Cryogenic ball valve stem sealIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat