Brand:

JST SealsItem NO.:

FMRPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Cryogenic ball valve stem seal

Sealing at cryogenic temperatures has its own unique set of challenges. JST has a wide range of solutions for cryogenic sealing applications. Cryogenic seals require skillful design by combining the right type of material, seal configuration, and spring energizer to overcome the dimensional fluctuation of all mating parts.

The FMR series spring energized seal can work in the environment of - 196 ° low temperature and corrosive chemicals for a long time. When the system pressure is zero, the spring provides initial pre pressure. When the system pressure increases, the U-shaped cavity is filled with pressure medium to make the lip close to the cylinder wall. In this way, it ensures that the seal always has good sealing performance in the whole process of pressure change, and the spring can choose ‘U’, ‘V’ and ‘O’ types according to different service environments.

|

Advantages:

1. Material compound passed API 6A FF/HH Immersion Testing; |

|

Working Conditions |

||

|

Temperature range |

Pressure |

Medium |

|

-196~121℃ |

150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB |

LNG, Low temperature ethylene |

| API 6D Stem Seal selection table | ||||||

|

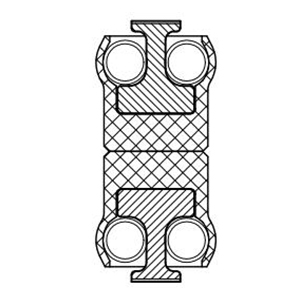

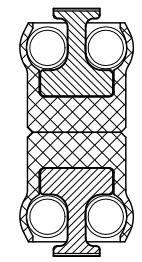

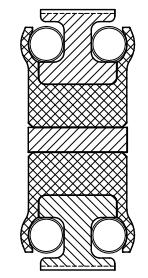

Groove DWG:

|

||||||

| Temperature Rating | JST Series | Spring | 0~900(LBS) | 900~2500(LBS) |

G=(OD-ID)/2

Standard CS:G=(OD-ID)/2

|

L Value |

| (-196℃~121℃) | FMR |

Golden Elgiloy

|

|

|

4.7 | 13 |

| 6.1 | 15 | |||||

| 8 | 15.5 | |||||

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat