We have been

manufacturing various types of fluid end valve and seats for both frac pumps

and mud pumps, covering various models for the most dominant pumps in the

market.

Item NO.:

Fluid end valve andPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

100Fluid end valve and seats

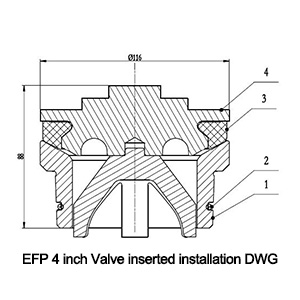

We have been manufacturing various types of fluid end valve and seats for both frac pumps and mud pumps, covering various models for the most dominant pumps in the market, applicable to mainstream pump types in China and other countries. All aftermarket valves and seats are 100% interchangeable with original designs. All these valves and seats are designed for high performance of maximum impact absorption and service lifetime.

The valve assembly is composed of valve body, valve seat, valve insert, etc. The valve body and valve seat are made of alloy steel through strict and reasonable heat treatment process, so that the surface hardness of the workpiece is high, and the core has good toughness, fatigue resistance, impact resistance and tight angle fit. Valve insert is made of oil resistant rubber, epoxy resin glue and other wear-resistant sealing materials.

When the fluid passes through the valve, the valve ball leaves the valve seat, the flow channel is opened, and the fluid can pass through. When the fluid flows reversely, under the action of pressure (or other forces), the valve ball sits on the valve seat, the flow channel is closed, and the fluid cannot pass through the valve. The principle is basically like this. Valve is often used in pumps, especially in multi plunger pumps, to maintain the one-way flow of fluid. Valve assembly is the whole system (each part of the valve) that constitutes the valve.

|

Features: Excellent wear and corrosion resistance performance. Suitable for high sand volume, high pressure fracturing work.

Specifications: Avg. Pressure: 80-110MPα Avg. Life: 8-12 stages (Vary according to specific conditions) Size: 3”, 4”, 4.5”, 5.5”, other size can be customized |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat