LNG Lip Seal For Filling Guns is commonly used in LNG (liquefied natural gas) filling guns.

Brand:

JST SealsItem NO.:

FHPPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50LNG nozzle spring energized seals manufacturer

LNG Lip Seal For Filling Guns is commonly used in LNG (liquefied natural gas) filling guns. Currently, it can be equipped with the most brand of filling guns and filling nozzles, both Chinese and overseas.

Main material:

Imported polymer material. It is reinforced for ultra-low temperature environment, and the lip is specially grinded, making it more wear-resistant and longer in service life.

Spring:

Adopt alloy+special treatment process (reduce metal transformation deformation of metal spring at low temperature, and improve yield strength) The special spring is made of HEATTREATED ELGILOY alloy spring. Compared with ordinary stainless steel spring, it is very stable in physical system at low temperature, with high spring load, it can maintain good sealing effect at low temperature, low pressure or when the surface finish is not ideal; Suitable for static and slow dynamic sealing.

|

Advantages: 1. Mature spring yield strength improvement process

2. Fatigue test ≥ 2000 times (low temperature of liquid nitrogen)

3. Good dynamic and static sealing

4. Chemical resistance

5. Low friction coefficient, effective wear reduction, self-lubricating, very good dry friction characteristics

6. Anti aging, without permanent elastic deformation

7. Anti aging, no permanent elastic deformation, greatly improving sealing capacity and service life

|

| Working Conditions | ||

| Temperature range | Pressure | Medium |

| -100~121℃ | 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB | LNG, Low temperature ethylene |

| API 6D Seat Seal selection table | ||||||

|

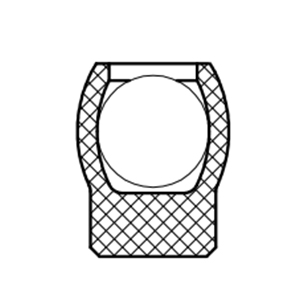

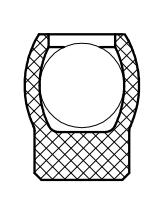

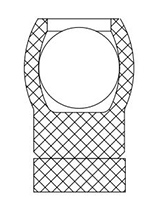

Groove DWG:

|

||||||

| Temperature Rating | JST Series | Spring | 0~900(LBS) | 900~2500(LBS) |

G=(OD-ID)/2

Standard CS:G=(OD-ID)/2

|

L Value |

| (-100℃~121℃) | FHP |

Golden

Elgiloy

|

|

|

3.1 | 4.8 |

| 4.7 | 7.1 | |||||

| 6.1 | 9.5 | |||||

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat