The pump plunger sealing system is adopted in the pump, which can effectively prevent the damage caused by water leakage and prevent the pump failure caused by the plunger friction overheating.

Brand:

JST SealsItem NO.:

W1Payment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Pressure pump seal for plunger pump

The pump plunger sealing system is adopted in the pump, which can effectively prevent the damage caused by water leakage and prevent the pump failure caused by the plunger friction overheating.

The application medium in the high-pressure cleaning machine is water, and the sealing parts need to meet the demand of increasing pressure. This type of seal originates from hydraulic equipment. In general, the shaft radial seal is mainly used on the gearbox. However, such seals are difficult to be used in water pumps, hot water equipment and other products. The main reason is that the service life is very short, and there is also a risk of water entering the oil chamber due to poor sealing effect. In addition, excessive slow relative movement of the seals can cause severe wear to the plunger.

In order to solve the above problems, we have developed a new sealing system, so that the seal can play a good sealing effect in water and the service life is greatly increased. Such a sealing system is adopted in the water pump, which effectively prevents the damage caused by water leakage and the failure of the water pump caused by the plunger friction overheating. Through detailed data analysis, the test shows that the sealing system can still ensure the normal operation of the system even under the conditions of large pressure change, high temperature and low lubrication. With such a sealing system, the high-pressure cleaning machine can work under the most severe working conditions.

|

|

Installation: Generally, W1 needs to be installed in the open groove, and a small amount of lubricating oil shall be applied during installation.

Compounds: Retaining ring: PTFE + carbon or bronze U-ring: fabric reinforced rubber Support ring: polyaldehyde resin |

|

Working Conditions |

||

|

Temperature range |

Pressure |

Surface speed |

|

-40℃to 80℃ |

≤250bar |

≤2m/s |

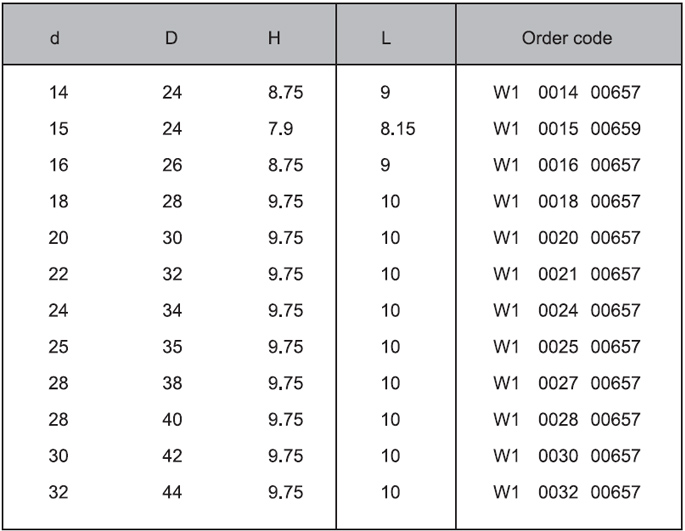

Size:

Previous:

High pressure water pump sealIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat