Wear rings are used to help keep the piston centered, allowing for even wear and pressure distribution on the seals. Wear rings are used in both piston and rod applications.

Brand:

JST SealsItem NO.:

WP/WRPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

50Hydraulic cylinder PTFE wear ring

PTFE is superior to all other known materials in terms of low friction, anti creep, chemical resistance and heat resistance. In order to obtain the best wear resistance, PTFE is mixed with different fillers, such as bronze or carbon.

PTFE material is only used when the surface pressure is low, or when friction is caused by medium temperature or speed, and no other material is allowed. From the point of view of starting friction, PTFE is better than all other plastic materials.

Sometime, the combination of PTFE wear strip and high load-bearing wear ring may have greater advantages. At this time, the wear strip will collect pollutants to avoid scratches on the sealing surface caused by its contact with the bearing wear ring (made of harder material).

|

Advantages:

1. High wear resistance |

|

Working Conditions |

||

|

Working Temperature |

Working Speed |

Material |

|

-100℃ to +200℃ |

≤5m/s |

Phenolic Resin

Phenolic Resin + Fabric

|

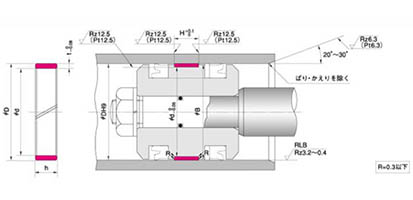

Size:

NO.

Nominal size and cavity size of wear ring

d

D

h

t

H

WR 18

14

18

8

2

8

19.2

15.2

19.2

20

16

20

22

18

22

24

20

24

25

21

25

26

22

26

28

24

28

30

26

30

31

27

31

31.5

27.5

31.5

33

29

33

10

10

35

31

35

35.4

31.4

35.4

35.5

31.5

35.5

38

34

38

40

36

40

41

37

41

15

15

43

38

43

2.5

44.5

39.5

44.5

45

40

45

50

45

50

51.5

46.5

51.5

55

50

55

56

51

56

60

55

60

61

56

61

63

58

63

65

60

65

20

20

66

61

66

69

64

69

70

65

70

71

66

71

75

70

75

76

71

76

80

75

80

85

79

85

25

3

25

90

84

90

95

89

95

100

94

100

105

99

105

110

104

110

112

106

112

30

30

115

109

115

120

114

120

125

119

125

130

123

130

3.5

132

125

132

35

35

140

133

140

150

143

150

157

150

157

40

40

160

153

160

165

157

165

45

4

45

170

162

170

180

172

180

185

177

185

190

182

190

200

192

200

205

197

205

50

50

210

202

210

220

212

220

224

216

224

225

217

225

230

222

230

55

55

240

232

240

250

242

250

260

252

260

60

60

270

262

270

275

267

275

290

282

290

70

70

297

289

297

300

292

300

312

304

312

332

324

332

Wear Ring (Seals for SPG and SPGW)

NO.

Nominal size and cavity size of wear ring

d

D

h

t

H

30W

26

30

8

2

8

31.5W

27.5

31.5

32W

28

32

35W

31

35

35.5W

31.5

35.5

40W

36

40

45W

40

45

2.5

50W

45

50

55W

50

55

56W

51

56

60W

55

60

63W

58

63

65W

60

65

10

10

69W

64

69

70W

65

70

71W

66

71

75W

70

75

80W

75

80

85W

79

85

15

3

15

90W

84

90

95W

89

95

100W

94

100

108W

102

108

110W

104

110

112W

106

112

120W

114

120

125W

119

125

130W

123

130

3.5

140W

133

140

20

20

150W

143

150

160W

153

160

170W

162

170

25

4

25

180W

172

180

190W

182

190

200W

192

200

204W

196

204

210W

202

210

224W

216

224

225W

217

225

230W

222

230

30

30

240W

232

240

250W

242

250

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat