Brand:

JST SealsItem NO.:

VZQPayment:

T/TProduct Origin:

ChinaShipping Port:

GuangzhouOrder(MOQ):

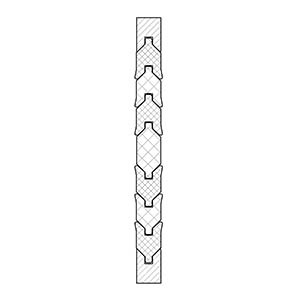

50V-Stack Seal Assembly for oil & gas

V-Stack seal assembly are used in various Oilfield Downhole equipment such as various Valves etc. Chevron seals are extremely suitable for usage in medium to heavy duty applications. Vee Packings accept low and high pressure while operating in the most extreme conditions and also if there exists any misalignment between the sealing gaps.

Due to its special design, the V-Stack seal assembly is very sensitive to the change of fluid pressure, so that it can deflect in the whole radial part, so as to increase the sealing load and effectiveness according to the proportion of applied pressure. In the assembly, the energized axial force is transmitted between each packing ring, so that each packing ring forms positive contact with the surface of the mating hardware. Special material grades are suitable for various working conditions.

|

Advantages:

1. Very robust seal |

|

Working Conditions |

|

|

Working Pressure |

Temperature |

|

-≤30000PSI

|

-45 °C to +260 °C /-49 °F to +500 °F Dependent on material |

Size:

69.85X80.1X43.82mm

82.55X92.14X45.75mm

107.95X95.25X45.21mm

123.77X133.35X73.4mm

Previous:

PEEK V stacks for downhole toolIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

© Copyright: 2026 Guangzhou JST Seals Technology Co., Ltd. All Rights Reserved.

Friendly Links:

VonesealsScan to wechat